CASE STUDY : Carytown Merchant Association, Carytown Sign

Vintage Neon Signage

CLIENT: Carytown Merchants Association

SERVICES: Design, Production Design, Fabrication, Installation

DESCRIPTION:

We partnered with the Carytown Merchants Association to create a new gateway sign, celebrating one of the city’s most iconic districts, Carytown.

The sign features custom bent, neon-lit channel letters housed by an aluminum cabinet and suspended between two monolithic support poles. A split between vintage character with modern engineering, the Carytown sign serves as both a landmark and a tribute to the neighborhood’s rich cultural identity.

Client Concept

Working with the CMA we developed a concept that reflects the district’s art deco charm, while making a bold statement as a modern gateway. Our main goals were to:

1) Creating a visual landmark that reflects Carytown’s identity, an area known for its local shops, restaurants, and walkable, community-focused layout.

2) Utilize modern fabrication techniques, like custom bent channel letters and engineered mounting systems, with vintage design elements like neon tubing and hammered brass accents that anchor the sign to the neighborhood’s historic roots.

3) Maintain structural integrity - the CMA specifically wanted the sign to span over both lanes of Cary Street. For this reason we had the sign reviewed and approved by the city’s engineers before any fabrication was started.

Challenges

The concept for the sculpture itself is rather simplistic in terms of design. However, when it came to fabrication it we had to solve for a few fabrication challenges:

Keeping the weight as light while maintaining the structural integrity of the sign.

Suspending the sign over the road, securely & safely

Carefully planning neon runs to prevent interference with the leads

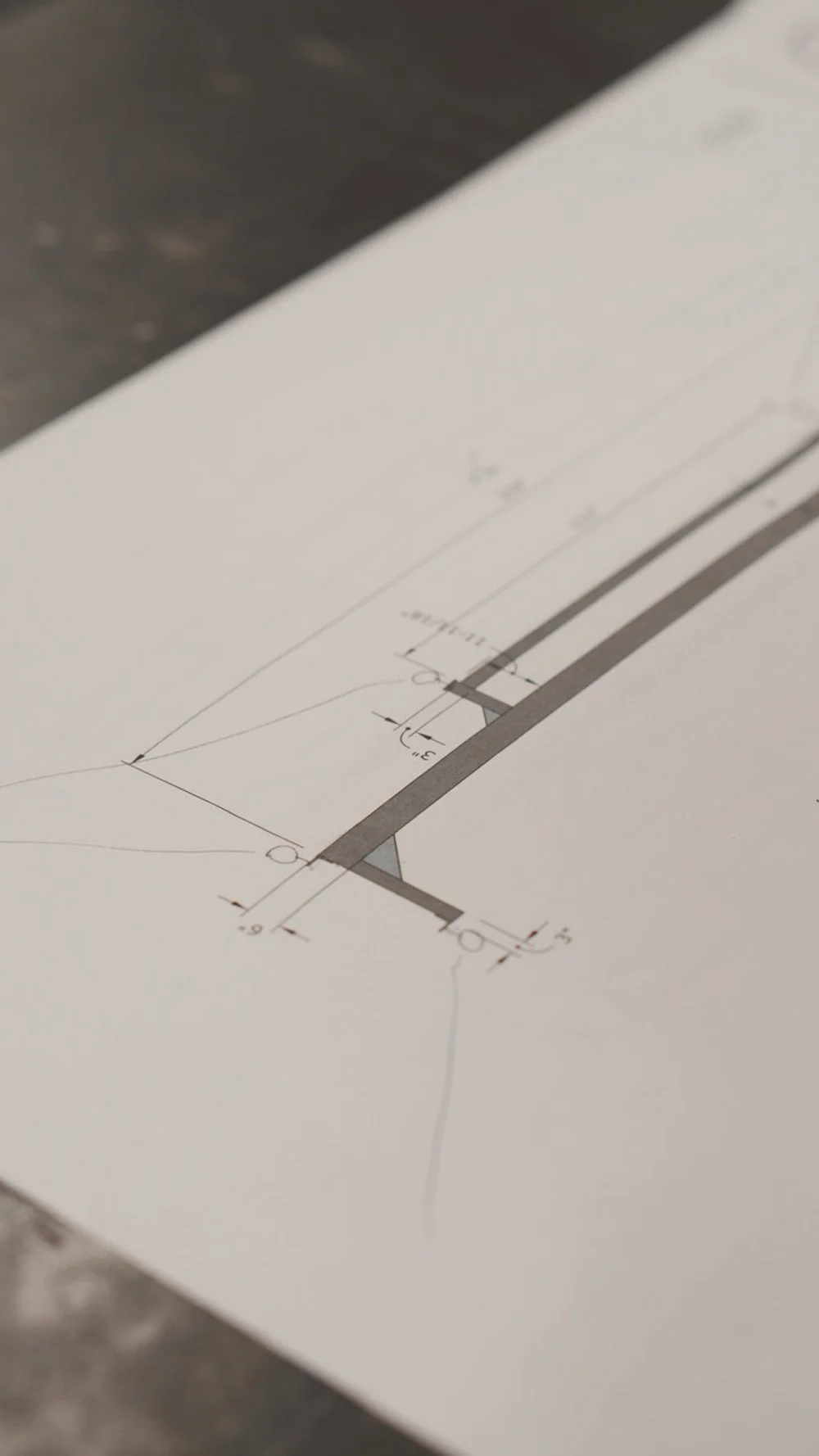

The sign’s main cabinet was fabricated around a welded steel frame, acting as an internal skeleton. The steel frame contained 6 anchor points where heavy-duty eyelets were installed, allowing the sign to suspend above the street.

To prepare for the install, we used our 60’ crane truck to suspend the structure outside our shop and mock up the full spiral. This helped us finalize wire lengths and test fit the system before heading to the site.

With the helix mocked up, we drilled and tapped over 250 holes for the donor plaques. Each plaque was attached using stainless steel cable and small set screws to ensure consistent vertical spacing.

Once on site, we reassembled the spiral, suspended it from the ceiling mounts, and began the long process of mounting and adjusting each plaque—bringing the full sculpture into alignment and completing one of the most complex installations we’ve taken on to date